I have used up all of the 5lbs of ABS that I bought from the RRRF with just a couple of plastic parts left to make to complete my Darwin. I bought 2Kg of ABS from

Tempatron but it is too oval to fit my current extruder, so it will have to wait until I build the new extruder for my Darwin. In order to complete that extruder I have had to go back to using HDPE. I always intended to make the filament guide for it out of HDPE anyway, because it is a lot more slippery than ABS, PCL and PLA.

It is quite a while since I did any work with HDPE and I didn't print many modeled objects with it before I switched to ABS, just lots of test blocks. In the meantime I have rebuilt and tweaked my extruder quite a lot and changed the way I do rafts. It took me a few attempts to dial in the parameters to get reasonable print quality.

In the end the result is not bad. The object on the far right is an ABS version, the one next to it is the best HDPE version.

The test piece is an alternative solution to the problem Vik mentions here:

new-x-carriage-hot-off-reprap.

It replaces the y-belt clamp that holds a piece of filament (which carries the cables to the extruder) and also provides the bearing surface missing from the "no support" version of the Darwin x-carriage. You can see the gap above the bar created by the teardrop shaped hole below: -

Here is the new HDPE piece installed: -

It also fixes the fact that the screw hole pitch of the belt clamp does not match the holes in the carriage. HDPE is very good for making bearings so I intend to remake all the bearing inserts in it when the ABS ones wear out.

The first thing to do is get the raft temperature correct to make it stick, but still be peelable from the chopping board. I start with the temperature at a value I know will be too low and go up in steps of 10°C until it sticks enough, but not too much.

The next thing I do is get the first layer temperature right so that the object can be separated from the raft. I found that quite hard to control with ABS and much more so with HDPE. I increased the temperature until the outline started sticking properly and found a small test object was still peelable. When I made larger objects they were stuck fast. I normally use a small penknife to separate stubborn objects but after stabbing my fingers three times I resorted to a chisel! I think some of the variability is down to changes in ambient temperature and bed temperature. The XY table of HydraRaptor is made of several Kg of aluminium, which acts as a heatsink for the motors. They run a lot cooler than my Darwin's motors despite having more power through them. The table slowly warms up to about 30°C, about 10°C above ambient. 10°C is enough to make all the difference between sticking and not. I probably need to measure raft surface temperature and adjust the first layer accordingly. Another thing to try would be to do the first layer outline hotter than the infill.

I dropped the build speed from 16mm/s to 8mm/s for three reasons: -

- HDPE puts maximum strain on the extruder because it is the most viscous at extrusion temperature so it is both the hottest and the highest pressure.

- Heat builds up in the object limiting the minimum size that can be made without inter-layer pauses, something I have not implemented yet.

- HDPE likes to cut corners and not go where it should and I think going slower helps the accuracy.

I also had to set the infill overlay parameter to 0.5 in Enrique's software to make the infill join to the outlines correctly.

A few things that are different about HDPE:

- Extruder ooze creates blobs rather than strings with my current nozzle. They are harder to remove because they are a lot thicker. Faster head movement on my Darwin should drastically reduce this effect.

- The brush I use to wipe the nozzle works perfectly with HDPE but not very well with other plastics. This is because HDPE extrudes in a straight line and is not very sticky. In contrast ABS tends to curl upwards and sticks well to the nozzle.

- HDPE spans gaps a lot tighter than ABS does because when it is stretched it remains under tension whereas ABS doesn't.

- Holes always come out smaller than they should be, but with HDPE this effect is worse. Dr Bowyer published a correction formula based on there being too much material on the inside of circles but I get contractions an order of magnitude greater. I think it is related to how much I stretch the filament but I need to do some more work on it.

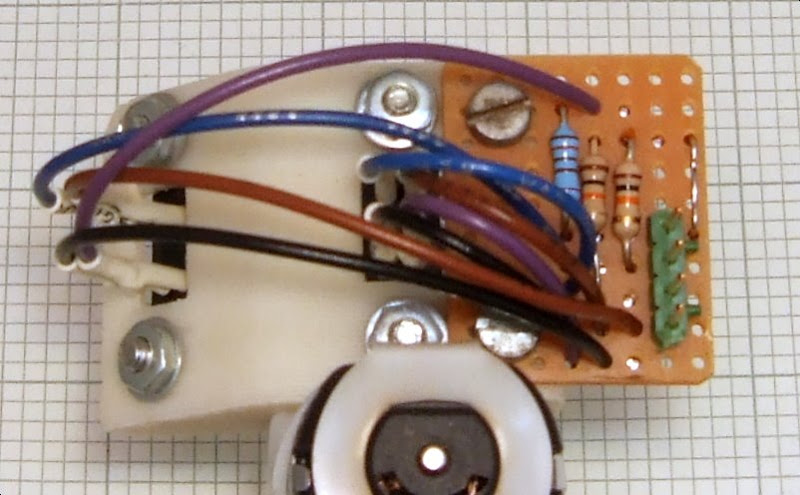

I then made the extruder clamp in HDPE. It is a bit warped of course but it doesn't really matter. The raft was strained upwards at the bottom left corner, not surprising as this is one of the longest pieces I have made.

Here it is cleaned up :-

The large hole for the PTFE barrel is undersized and my PTFE stock is oversized so I think I will have to turn it down to get it to fit. I drilled out the other holes.

Similarly the filament guide is warped on the underside but it is only the top side that needs to be flat.

As predicted it is slippery and my oval ABS glides through it very well.

I just have to make the metal extruder parts now and that completes the mechanical build of my Darwin.