The first idea was to drill an array of holes through an aluminium plate and connect them on the back by milling a network of channels. I would close the top of the channels with some Kapton tape. The problem with that idea was there was then nowhere to mount the heating resistors unless it was on top of the Kapton sealing tape, which didn't seem ideal. My solution to that was to mill a channel into the edge of the plate and wind a coil of nichrome all the way round it. That was my plan until I realised there would then be nowhere to attach the vacuum hose.

A solution might be to use a Kapton or silicone stick-on heater and use it to seal the channels in the underside.

What I actually did was to mill a grid of very fine channels into the top surface allowing me to attach the vacuum hose to the side edge and drill a small hole down to meet it, leaving the bottom free for the resistors and thermocouple.

The channels are about 0.5mm wide and 0.5mm deep on a 5mm grid. I milled them with a 0.3mm conical bit that I bought for milling PCBs.

I used a feed rate of 2mm/s and 0.1mm cut depth per pass. My MiniCraft drill runs at about 20,000 rpm. The results were not very good. I have only ever milled plastic before with HydraRaptor. It struggled cutting aluminium such that the shaft of the drill was being displaced in the direction of the bed travel. It raised a burr about as high as the channel is deep. My friendly local milling consultant told me afterwards that aluminium does not like lots of flutes. He recommended a D-shaped cutter with a single cutting edge and a higher spindle speed.

I sanded the surface flat with 240, 600, 800, 1200 and 1800 grade wet-and-dry sandpaper and then polished it with metal polish. I did this to get as good a seal as possible with whatever was placed on top.

I attached some polythene pipe using an M5 copper welding nozzle screwed into a tapped hole in the side of the plate. I use a tapered tap so that the thread would bind to form a seal. I used Fernox LS-X jointing compound to make sure it was airtight. I think it is silicone, so should handle the temperature.

I was hoping to get a perfectly air tight seal and be able to use a static vacuum generated by a syringe. It doesn't seal fully though. I believe normal vacuum tables use rubber o-rings set into a groove to form a seal. I reasoned that would not work in this case because, whereas sheets of stock for milling are stiff enough to remain flat and squash the rubber, thin films would just bend upwards. My idea was that the thin film would be sucked into the channels and be compliant enough to seal it. I think it fails because the edges of the channels are too rough due to my poor milling.

I first attached a small vacuum pump that I made for my jukebox. It is just an aquarium pump with a pipe attached to the air inlet and the case is sealed with rubber glue.

It is not a very strong vacuum, but it is enough to pick up a CD with a suction cup made from the end of a child's rubber dart. I plan to use it for SMT pick and place soon. I measured it at 960 millibars, which is also the extreme low reading on our barometer. I knew that the vacuum it created was less than the atmospheric variation because I started off with an absolute pressure transducer on my jukebox to detect if a disk had been picked up. I had to change the trip point about twice a year because one setting would not work for both extreme high and low weather conditions. In the end I added a second sensor to make it differential.

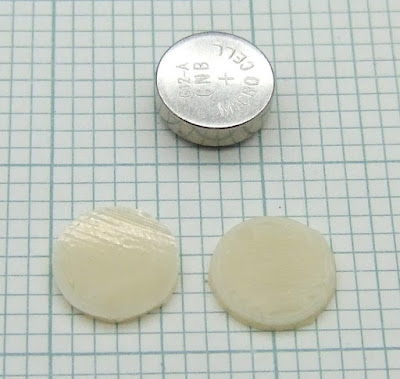

I placed a piece of 0.075mm polyimide film on top. This is about twice as thick as the tape I use.

The video below shows the effect of the vacuum. It pulls flat and has some resistance to sliding but is not a very strong grip.

I built a Mendel part at 100°C for my first test. The film stayed flat during the build but a few corners lifted. When the part cooled it broke the vacuum and wrinkled the sheet. It was past the point where it had hardened so the base was perfectly flat apart from where the top corners had lifted slightly during the build.

I measured the temperature of the surface and found that it was 10°C lower than that measured underneath by the thermocouple. I raised the set point to 110°C and made another part. This time only one corner lifted (left side of the boss in the middle) .

Here is a speeded up video of the film releasing as the bed is cooled down to 40°C by a fan.

And here is me simulating removing the object by sliding the film. Ignore the ×16 annotation, I am not that slow!

The next thing I tried was a really big part of Mendel. I didn't trust my weedy aquarium pump to hold it down so I used a 1/4 HP 180W 3 cubic feet per minute pump rated to go down to 0.1 millibars. I bought it for £150 over two years ago to make a vacuum bed for milling but never got round to it, so it has been sitting on a shelf, like a lot of other parts and materials I have bought for experiments but not had time to use.

When connected directly to the vacuum gauge with a length of plastic hose it goes down to about 30 mb. I think I would need better quality fittings and pipe to get down to 0.1 mb. When connected to the vac table it gives 40 mb, so although it does leak, it still gets most of the available downforce from atmospheric pressure, i.e. ~15 lbs / square inch.

The part I made ended in disaster because the vacuum broke during the build. I think it was mainly because the object was not quite centred on the table so its outside perimeter was on top of the last vacuum channels. Before it failed some corners had lifted a little, early in the build, so it looked like the ABS does not stick to film as well as it does to tape.

I centred the table and made a slightly smaller piece. Actually this was the same depth as the last piece, so the perimeter falls about half way between the last two channels. Ideally I think you don't want to be that close to the edge.

I raised the temperature to 120°C, so the top of the film was probably ~110°C.

The film stayed vacuumed down during the build but still broke the vacuum and wrinkled during the cool down period. That means that even with close to the maximum vacuum it cannot hold the contraction force. Not a big surprise as I realised a long time ago the warping can generate a lot more than 15lbs / square inch of pull. The only reason I thought this might work is because the plastic does not warp while it is kept hot and indeed the vacuum holds during the build. The problem is that the object does not stick to the film well enough. One corner peeled early on and lifted further as the build progressed. The rest of the base is flat though, so the part is easily good enough to use. The higher temperature and vacuum meant that the grid lines are just visible on the object base if you get the light right.

So just to make sure I can make an object this size on tape without warping I made the larger part again on my magnetic bed. That failed because the bed slipped part way through. I knew that was a likelihood and that I need to add a couple of dowel pins in the corners, but I didn't want to do that while I was experimenting with vacuums. I gambled on it not slipping and lost.

It did build enough to show that it sticks much better though. The corners stayed down and the build lasted long enough to go way past the point where the corners lifted on the vacuum bed. The base was perfect.

I could only think of three possible reasons why the corners would lift on the vacuum bed and not on the magnetic bed.

- The surface of film might be different to tape. After all, tapes have the magic property that the glue only sticks to one side and peels from the other without leaving any residue.

- The film is thicker, so has more thermal resistance, which might have some influence.

- Perhaps the film can lift a little in between the vacuum channels allowing the plastic to peel away and then be sucked flat again.

More importantly though I could see that the other corners were deforming the film upwards as I had suspected. It is hard to see here, but the slightly raised blister of film was over a channel, so subject to the full vacuum force.

This shows that even with a heated bed, there is sufficient warping force at the corners to beat atmospheric pressure. The part ended up with one chamfered corner and dimples in the others.

So in general the experiment is a failure as it does not work as well as the magnetic bed. It does allow easy automated removal though. All you need to do is tape down one edge of the film. When the object cools it wrinkles the film and breaks the vacuum. A fence could then push the object off the bed with not too much force, as the film peels easily. When the object is gone the film springs back to being flat and the vacuum can pull it down again ready for the next object.

Although corners lift, the objects are usable for making a Mendel, it is only an aesthetic issue in this case. I think rounding the corners of the parts would fix it. I guess PLA might stay stuck as it warps less, and ABS only fails in extreme cases.

Thanks to Paul for providing the polyimide film samples and lending me the vacuum gauge.