I have been printing both ABS and PLA on PET tape for more than a year now. It works well and lasts for many months, but eventually the silicone adhesive fails and it blisters. Applying it is fiddly to avoid any overlap but also not leave gaps between the adjacent runs of tape. I have been on the lookout for a solid material to avoid these pitfalls.

Stoffel15 (Wolfgang) told me that FR4 fibreglass PCB material works well. FR4 is the most common PCB material and is a glass fibre and epoxy resin laminate. It will handle solder re-flow temperatures (~ 240°C) for short durations and can be used continuously at 140°C. As I haven't worked on single sided PCBs for many years, I had forgotten what the surface of the raw material looks like. It is actually smooth and glassy, so ideal as a bed material.

I ordered some single sided PCB material from Farnell. It works fantastically well. It seems to have a bit more grip than PET and has the advantage that there are no lines on the part from the joins in the tape. It also has no give in it, so I don't get any blistering at sharp corners like I did with tape, sometimes leaving shallow dimples.

Another advantage is that when the object cools it tends to break free because it contracts more than the bed does. With tape there is some compliance, so it usually stays stuck when the object cools and it is often hard to remove parts. With FR4, if you get the layer height spot on, the parts break free of their own accord, and if not, are very easy to snap off. This vertex bracket was loose after the bed cooled to 50°C.

Yet another advantage is that I stick the tape to a steel plate 0.9mm thick that weighs 280g. The FR4 is 1.6mm thick but it only weighs 134g, so less than half the mass.

I also tried some plain FR4 without copper and that seems to work just as well. It is 0.9mm thick and weights only 75g. The disadvantage is it is bright yellow, which makes it hard to see the white plastic on it.

I have printed a full set of Mendel parts so far on FR4 and every part has come out perfectly flat, and was easy to remove.

I don't know if it will degrade over time, but there is no sign of surface damage so far. The dark features on the picture above are marks on the aluminium plate underneath.

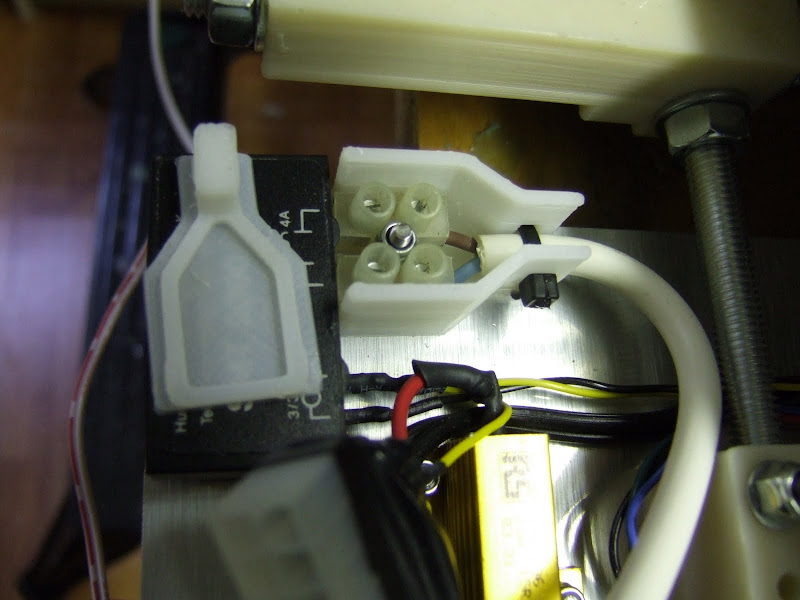

The nice thing about the z - probe I have on HydraRaptor is that I can change the bed without any calibration.

This is what the underside of an object looks like.

I used the same temperature I used for PET tape, which is 140°C for the first layer and 110°C after that.

I haven't tried PLA yet, but my guess is it will stick because it seems to stick to a superset of things ABS sticks to.

Great tip Wolfgang!

In the past I tried FR2 (SRBP, Paxolin) but that did not work, probably because it had a matt surface. I also tried some CAT7FR, which is another type fibreglass PCB material, but again it had a matt surface and did not work very well. I was able to build a flat object on it, but the first layer outline did not stick properly, so some holes were a bit scrappy.

The copper on the bottom of the single sided material could be used as a heater like the Prusajr heated bed design.

Stoffel15 (Wolfgang) told me that FR4 fibreglass PCB material works well. FR4 is the most common PCB material and is a glass fibre and epoxy resin laminate. It will handle solder re-flow temperatures (~ 240°C) for short durations and can be used continuously at 140°C. As I haven't worked on single sided PCBs for many years, I had forgotten what the surface of the raw material looks like. It is actually smooth and glassy, so ideal as a bed material.

I ordered some single sided PCB material from Farnell. It works fantastically well. It seems to have a bit more grip than PET and has the advantage that there are no lines on the part from the joins in the tape. It also has no give in it, so I don't get any blistering at sharp corners like I did with tape, sometimes leaving shallow dimples.

Another advantage is that when the object cools it tends to break free because it contracts more than the bed does. With tape there is some compliance, so it usually stays stuck when the object cools and it is often hard to remove parts. With FR4, if you get the layer height spot on, the parts break free of their own accord, and if not, are very easy to snap off. This vertex bracket was loose after the bed cooled to 50°C.

Yet another advantage is that I stick the tape to a steel plate 0.9mm thick that weighs 280g. The FR4 is 1.6mm thick but it only weighs 134g, so less than half the mass.

I also tried some plain FR4 without copper and that seems to work just as well. It is 0.9mm thick and weights only 75g. The disadvantage is it is bright yellow, which makes it hard to see the white plastic on it.

I have printed a full set of Mendel parts so far on FR4 and every part has come out perfectly flat, and was easy to remove.

I don't know if it will degrade over time, but there is no sign of surface damage so far. The dark features on the picture above are marks on the aluminium plate underneath.

The nice thing about the z - probe I have on HydraRaptor is that I can change the bed without any calibration.

This is what the underside of an object looks like.

I used the same temperature I used for PET tape, which is 140°C for the first layer and 110°C after that.

I haven't tried PLA yet, but my guess is it will stick because it seems to stick to a superset of things ABS sticks to.

Great tip Wolfgang!

In the past I tried FR2 (SRBP, Paxolin) but that did not work, probably because it had a matt surface. I also tried some CAT7FR, which is another type fibreglass PCB material, but again it had a matt surface and did not work very well. I was able to build a flat object on it, but the first layer outline did not stick properly, so some holes were a bit scrappy.

The copper on the bottom of the single sided material could be used as a heater like the Prusajr heated bed design.