I needed something that was not too viscous so that it would flow in between the mesh of the fill pattern and would set hard.

Polyurethane was recommended to me because it has the consistency of milk before it sets and is strong enough to cast parts for Darwin. I bought some Smooth-Cast 300 which has a pot life of 3 minutes after it has been mixed, and cures in 15 minutes. I choose a fairly fast setting one because it gets hot while curing and I hoped it would soften the HDPE to relieve the stress. It only seems to get to about 50°C though so I don't think that it has much effect in that way.

This is the equipment I used :-

I know the internal volume of my objects pretty accurately so I measure out the required amount of plastic using separate labeled syringes for the two components. I mix it in a small pot before filling a third syringe to inject it. The syringes and pot are made out of polypropylene, which polyurethane does not stick to, so they can all be reused. I haven't found a way of unblocking the needles though.

I made a 50% filled object and drilled a hole the diameter of the needle in the middle that allowed the needle to go to the bottom. I also drilled a small riser hole at each end to let air out. Obviously, with cleverer software these holes could be made during the FDM phase.

The first attempt was a complete failure because the needle blocked when the object was only about 50% filled. Here is a cross section :-

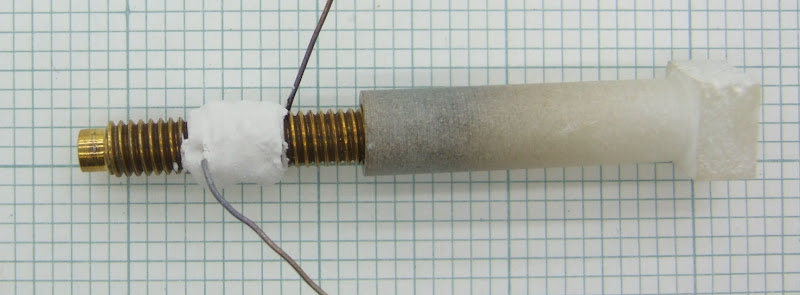

For my second attempt I used a thicker needle, 1mm OD rather than 0.8mm :-

The object filled OK, but just as it became full the plastic in the needle set suddenly but I carried on pushing. The needle popped off the end of the syringe and PU sprayed all over the place. It was a good job I was wearing goggles and gloves but I should also have been wearing long sleeves, a mask and a hat! Fortunately PU does not stick to much, only untreated wood, skin and hair! Where it gets on your skin it burns slightly. Because it is transparent before it sets it is very hard to see where it has gone but when it sets it turns opaque white so it becomes obvious.

It actually sprayed around one quarter of the room. I even got some on my lips which I didn't notice until I tried eating.

What seems to happen is that if you subject the liquid plastic to pressure it accelerates the curing, which increases the temperature and pressure creating a positive feedback effect which makes it set suddenly in the needle. I only had two needles and they were now blocked so I did the remainder of my experiments using just the nozzle of the syringe into a bigger hole in the object.

The ideal solution is probably a very big needle that locks onto the syringe. It doesn't need to be sharp but the 45° slant at the end is handy because it stops the end being blocked if you press it against the bottom of the object.

Results

I left the objects on the bed overnight to make sure the PU was fully cured even though it sets in 15 minutes. The first object I made had a 50% fill and warped 0.36mm compared with 0.47mm without the PU injection.

Thinking that 50% fill leaves the PU fairly weak, I did another test at 25% fill. That gave 0.24mm warp, the lowest figure I have achieved yet for this shape.

I also tried a 100 x 10 x 20 mm test with 20% fill ratio. That gave about 50% less warping compared to the version without PU.

Conclusions

A useful technique for reducing warping and reducing the build time of FDM objects. The main disadvantage is that FDM is one of the cleanest and safest fabrication techniques whereas injecting PU is messy and somewhat dangerous unless you wear protective gear.

I was disappointed not to get rid of the warping completely. Instead of alternating the horizontal and vertical fill patterns, several layers of one followed by several layers of the other might make the PU lattice stronger. Raising the PU to 50°C for a few hours is supposed to harden it further, so I could try removing the bed and putting it in a very low oven for a while. I have a Peltier effect 12V beer fridge which can be reversed and used as an oven, so that would be ideal.

Using a harder plastic like epoxy might work better but it may be too viscous to inject. I believe heating it reduces viscosity.

Reducing HDPE warping feels much like banging ones head against the wall so I will try PCL and ABS next for some light relief.