I bodged the heater connection by putting some more solder on it. It's not a permanent solution because the solder is molten while the heater is on so it slowly oxidizes away. The last time bodged it that way it lasted six months though. It really needs a crimped connection.

The GM3 motor failed by running slowly, getting very hot and drawing lots of current. It eventually caused the protected MOSFET that is driving it to shut down. Opening it up soon revealed how it had failed :-

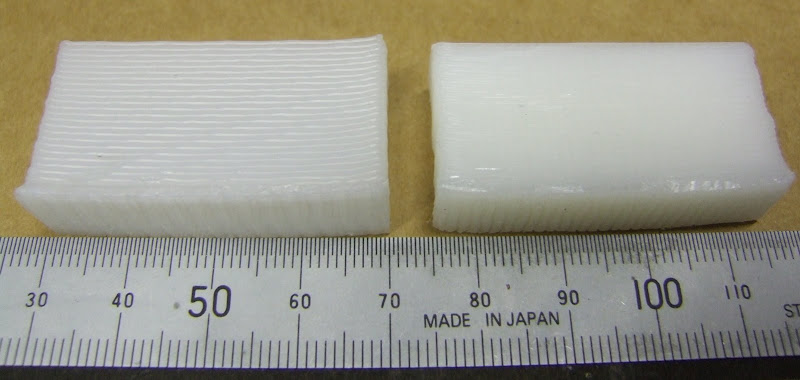

It has two pairs of copper brushes. Three of them have holes worn right through and the fourth has broken off. Its stub was touching the wrong side of the commutator, causing a short.

More expensive motors have carbon blocks on the end of arms which can wear down a lot further before they fail. Bigger motors have spring loaded carbon rods. The gearbox shows no sign of wear so it is let down by the cheap motor.

This motor is not really up to the job of driving the extruder. It is being severely abused by running it from 12V PWM when it is only rated at 6V. I anticipated it would not last long and ordered a spare when I bought it. I fitted that and HydraRaptor is up and running again. Curiously the second motor seems a lot quieter than the first.

At some point I think I will upgrade to a stepper motor. They are more expensive but, as long as you don't load the bearings, they last virtually forever. In the long run they probably work out cheaper and I can also dispense with the shaft encoder and the interference suppressor.