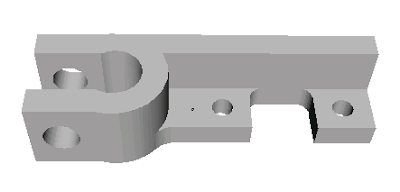

To extrude HDPE quickly, without losing accuracy, requires a fan blowing on the work piece while extruding at around 240°C. The PTFE insulator in the extruder starts to lose its strength under these conditions and it also extends about 0.5mm due to thermal expansion. The JB-Weld heater insulation also degrades rapidly. To address these problems I am working on a design using stainless steel as the insulator, which I first blogged here. Here is a second lash up I made to progress the idea :-

At the bottom is a brass nozzle made by the man himself, Adrian Bowyer, and is described here. It has already been superseded with the anti-ooze design shown here.

Above that is a brass barrel that came from BitsFromBytes, with my experimental Cerastil heater on it. I attached a thermistor to the barrel with JB-Weld.

The brass barrel is screwed into the end of a 1/4" stainless steel tube. The other end has been tapped with a 1/4" UNF thread and screwed into a small north bridge heatsink from a PC motherboard (40 x 40 x 15mm). I drilled through the centre and tapped it. To lock it in place and give a good thermal connection I made a square nut from a piece of 10mm aluminium bar. I spread heatsink compound on the threads.

The top of the stainless steel tube is screwed into an old PTFE barrel to join it to the pump. The barrel had swollen so that it wouldn't hold an M6 thread anymore, but fortuitously it seems to have swollen just enough to match 1/4" UNF.

This is by no means the final design, it is far too long and flimsy, it's just to test the concept using existing parts.

I also wanted to try insulating the barrel and nozzle with PTFE. I made an end cap that fits over the nozzle by plunging an 8mm end mill into a 12mm PTFE rod :-

The idea of this is to keep the fan wind off the nozzle and also give it a non-stick surface so that when filament curls upwards and will not stick to it. I also insulated the stainless steel tube with a piece of 12mm PTFE rod with a 7mm hole drilled through it. Here is the completed assembly :-

The gap in the PTFE where the heater and thermistor are and where the wires emerge is covered with fiber class wool. I hate the stuff, I only have to think about it for it to make me itch all over. It is a much better insulator than PTFE though, but I wanted something smooth and slender to not disrupt the airflow from the fan too much.

The wires are sleeved with PTFE insulation and then plugged into a floppy drive connector. So everything at the hot end is good for about 300°C.

How well does it work? Well it took me a long time to be able to get it to extrude HDPE semi reliably. Thermally it works well. With the fan off and the barrel at 250°C the heatsink only gets to about 45°C, easily cool enough to mate with HDPE, ABS and probably PLA and PCL as well. With the fan blowing it cools down to room temperature. The heater power goes from about 60% to 80% so the insulation works well enough. A better idea might be to lag the pipe with a thin layer of fiberglass wool and then wrap it with PTFE baking parchment to give it a smooth outer surface. Or maybe an outer metal pipe with fiberglass in between.

Mechanically it is not that great. It seems to a need lot of force to extrude. I had to open up the hole in the nozzle from Adrian's 0.4mm to my standard 0.5mm. I also had to up the temperature to 250°C. I think this is mainly due to where I am measuring it and how I calibrated the thermistor. Previously I measured the nozzle temperature and calibrated it with a thermocouple inserted into a hole in the nozzle. With this version the thermistor is in a notch on the surface of the heater barrel and I calibrated it with a thermocouple inside the empty barrel. Looking at the value of beta that I got I think that it is considerably hotter inside the barrel than the thermistor is outside. I am not sure how this is. With the heater on the outside of the barrel I can't see how the inside could be hotter. Perhaps the thermal connection of the thermistor to the barrel, via JB-Weld is not as good as it it could be. When sited in the acorn nut nozzle it was half buried in a hole.

Even with the nozzle removed it is quite hard to extrude 3mm filament by hand. Part of this has to do with how long the total barrel is and the fact that it has three joints. The inside of the stainless steel barrel is not as slippery as the PTFE. It might also be the case that the molten section extends further up the barrel causing more viscous friction. I plan to shorten the whole thing considerably: I will combine the clamp with the right angle bracket and take the tube right up to the base of the pump. I will support the heatsink with a cradle structure resembling an upside down table. More importantly, I will shorten the heater barrel by combining it with the nozzle and screwing the tube into it. Making it from aluminium, which is two and a half times a better conductor than brass and easier to machine, should make it easier to get a consistent temperature measurement.

As there is a continuous temperature gradient down the stainless steel, the point at which the plastic melts will be about halfway up so I think the heated nozzle can be quite short indeed. The limiting factor is how long it takes the heat to get to the centre of the filament with the very poor thermal conductivity and high specific heat capacity of the plastic.

Here is an HDPE version of the opto bracket with my best PCL version behind :-

I have no idea why it is so grey. It is not as neat as the PCL one but most of the errors are due to blobs forming when the extruder moves between extruding. These cause the nozzle to be displaced sideways when it gets close because it is so flimsy. Shortening it and supporting it properly will improve matters for sure. I also need to incorporate Adrian's anti-ooze valve somehow.