ABS sticks very well to

hot Kapton, so I wondered what else would stick to it. The first thing to try was PLA. This sticks pretty well to

cold masking tape and doesn't warp much, but large objects do have some warping. I figured heating the bed to around 50°C would fix that. Rather than changing from Kapton to masking tape I decided to see if I could stick PLA to Kapton and get a shiny surface as well.

The first bracket was made on cold masking tape so the base has a matt finish.

The second one is on Kapton at 50°C for the first layer, dropping to 40°C after that. My logic was to have the bed just above the glass transition to make it stick and just below afterwards to stop it warping. As you can see one of the hole outlines did not stick properly. The PLA was extruded at 200°C for the first layer and 180°C for the rest.

For the third one the bed was at 55°C falling to 45°C. The outline stuck properly and the base is nice and shiny. The surface imperfections you can see are from gouges in the aluminium bed caused by a slight accident with a decimal point. It caused the nozzle to be rammed into the bed and then the X-Y movement ploughed furrows. These show up through the Kapton tape.

The last one is my first ABS test for comparison.

It was looking good, so I tried something bigger, a Mendel belt splitter jig: -

The left hand corner lifted and the object ended up more warped than it would have been made on cold masking tape.

I tried again with the bed at 55°C all the way through the build. My extruder started jamming so I increased the PLA temperature to 210°C for the first layer and 190°C for the rest, the values I had been previously using on cold tape.

This time it was successful and stayed stuck down: -

The base came out perfectly flat and more transparent: -

The extrusion lines of the three solid base layers are less visible and you can see through to the sparse infill. This is only 25% but the object feels incredibly strong. I get the feeling the hot bed makes things stronger.

There is a bit of a meniscus around the edge. This is mainly because I had a bodge of a -0.1mm offset in the first layer outline to get PLA outlines to stick to tape reliably. I removed the bodge and made this object: -

The base layers are very transparent here, even more so to the naked eye than the camera shows. There is something a little odd with some of the extrusion lanes above the bottom left hole. I think those discontinuities must be the plastic squirming a bit while extruded, which is usually a sign of not being stretched enough.

The top of the object has a small defect: -

There is a small hole above and right a bit of the centre. I think this is because the plastic doesn't span gaps as well without a fan, so it fails to bridge the sparse infill properly. I wasn't watching so I didn't see exactly what went wrong.

The next plastic I tried was HDPE. Not surprisingly it doesn't stick very well to hot Kapton. With the bed at 130°C it stays molten but is quite rubber like. With the bed at 110°C it sets and turns white (because it crystallises I believe). I tried various combinations of these two temperatures but could not get it to stick reliably. I could lay down the first layer of a raft but then subsequent layers would rip it up as the adhesion is very low.

I think the way to do HDPE without a raft is to extrude it onto a thin sheet of HDPE, or maybe polythene, held down by a vacuum and heated to prevent warping. That will have to wait until I build a little vacuum table, hopefully this weekend.

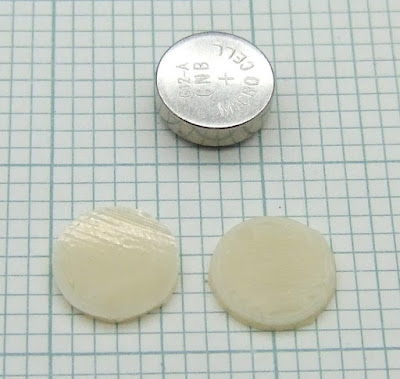

Last on the list was PCL. That sticks very well to Kapton heated to 40°C but it never sets and makes a soggy object.

Before the heated bed I used to build with a fan, and at only 40°C the bed has no trouble holding temperature, so I tried with the fan next.

That worked OK and built a complete object: -

The infill did not stick very well to the outlines of the holes, especially on the downwind side. It probably needs a denser infill, and perhaps some overlap. 25% fill is not really appropriate for PCL as it very soft and flexible.

The bottom is smooth and shiny as expected and it took some effort to peel it off, so I expect large objects could be made. I couldn't experiment further though because the filament started buckling in my extruder.

I can't explain why it worked for a while and then stopped but I tried higher temperature and slower extrusion but could not get it reliable again. The pipe could probably be a few mm closer to the pulley but not much more because it would hit the pinch wheel.

I don't have a lot of use for PCL, other than using it up. Dropping it from the requirements for the extruder would allow me to use a smaller pulley. If you look at the table at the end of

this article, you can see that it is only PCL that struggles for grip with a worm pulley. I think I could drop to half the diameter, which would just about bring the gear ratio into the range of a single pair of spur gears. I have a 4" Meccano gear that gives 7:1, so I might try that in my next extruder.

So hot Kapton works well for everything I have tried so far apart from HDPE.