I promised to RepRap a new clip a long time ago, but only got round to it today. Neither of us could remember what the old clip looked like so I designed a simple one from scratch. To my surprise it printed perfectly on the hot bed, I thought it might need some cooling. HydraRaptor will have automatically dropped to half speed because the layers are so small.

I cut off the remains of the old clip and filed it smooth. I then removed all traces of grease with some isopropanol and welded it on with some MEK pipe cement. A friend gave me it anticipating that I might want to weld ABS someday. It will dissolve and weld ABS and PVC. I think the case is ABS, so it is ideal for the job. It needs 4 hours to cure, so I left it overnight.

It seems to have done the job. I offered to make it in black but my wife wasn't bothered.

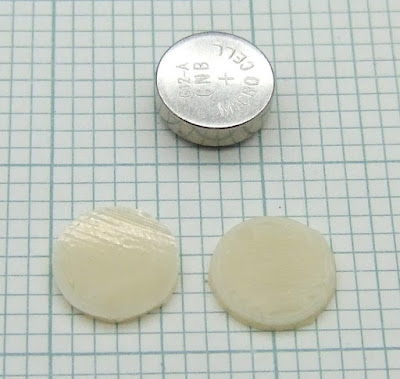

The next problem was that the batteries had gone flat in the years she has been waiting for me to fix it. Buying specific batteries is expensive but you can get a mixed selection of 40 for £1. The problem is though that we mainly use the biggest ones so have too many of the smaller ones. I had some that were the right diameter but too thin so I Reprapped some spacers.

I can now make objects side by side one layer at a time with no strings between them. These are probably the smallest things I have made. They are about the size of tiddlywinks.

A bit tricky to keep in place while the battery cover is replaced but they did the job.

So I am back in the good books for a while. I managed to run off two of these as well. They take about 90 minutes each and are perfectly flat and string-less again.

Just the odd lump on the surface at the start or end of an outline. I think that can be easily solved by always starting on an inner shell before doing the outer shell and then finishing the outer shell with a wipe towards the inner one.

Quality of the part in that last picture is fab!

ReplyDeletep.s How many brownie points did you earn?

Great very high quality prints again, Now the big question is will you match the quality generated with Hydraraptor on the Mendel you are printing?

ReplyDeleteBrownie points will most likely need to be earned to compensate for the extra power consumption of the heated bed me thinks.

Midge was surprised to see how much our power consumption had dropped since last year using power savers and even lower power Led lighting with new electronic thermostats instead of the old bi-metal strip versions.

Paul,

ReplyDeleteQuite a few, but I have built up a huge deficit spending so much time on HydraRaptor.

BodgeIt,

The heated bed only takes ~50W when it us to temperature. My computer with two screens and the 160W of fluorescent lights in the room swamp that!

Also, during the winter, electrical appliances are 100% efficient because they help to heat the house.

I think the quality comes from the good real time behaviour of my firmware and the extruder having accurate control because of the gear ratio and microstepping. I don't think it is because of the high resolution of my table.

ReplyDeleteOh my with all the lights on in Midges house its less than 160W... I see what you mean I think..

ReplyDeleteThe new Bathroom has 9 x 7w CFL spotlights.

My house is all LED Lighting, Midges house is half CFL and LED the biggest are 20W up lighters.

Correction the Bathroom only has 8 x 7W CFL's I sneaked a 2W LED Spot light in.

ReplyDeleteI find the older I get the more light I need to work. I think smaller pupils give better depth of field. My lab is 12" square with two 80W 5ft tubes. It is bright, it used to hurt my eyes when the tubes were new!

ReplyDeleteOh don't I know it..!! Being a few years older than you as well.

ReplyDeleteI use 1 MR16 78 Led spot 12V @ 236 mA for Soldering sometimes with a couple of 24 Led Spots I bought 3 of the MR16 78 Led spots they are very bright.

The Lathe and Drill I have 7W CFL spot lights they will eventualy be 78 Led Spot lights.

"HydraRaptor will have automatically dropped to half speed because the layers are so small"

ReplyDeleteDo you mean you reduced the layer height to build this little part...it does look fine actually?

No when a layer is so small it takes less than 10 seconds to build the head speed is halved to give the plastic chance to set. Otherwise heat builds up faster than it can dissipate and the extruder ends up stirring a molten mass.

ReplyDeleteSo, the hot air stream would help this problem & allow you to optimize speed again? what layer height was this btw

ReplyDelete0.4mm * 0.8 = 0.32mm

ReplyDeleteI'm surprised that the heated bed only uses about 50 watts, it's pretty efficient. I'm guessing any form of hot air solution would be several times higher going by what the typical hairdryer or fan heater consumes.

ReplyDeleteIt's 40W when stationary. I don't know how much it goes up when the table moves, but certainly less than 100W. Yes hair dryer will be a lot more.

ReplyDeleteI don't know if I will get warping with big tall objects. The tops of objects come out flat even without a heated bed so I am guessing it is only necessary to heat the bottom layers. Some heat is conducted up through the plastic and the warm air rises and warms my extruder quite a bit, maybe 10C, even though it has the big Z-sled for a heatsink.

nophead: for the battery spacer: You could design small legs to go around the real battery. If I see right from the picture there are even holes where the legs could easily go into.

ReplyDeleteLaszlo