I decided to make a new extruder for HydraRaptor concentrating on performance and reliability. I have tried to pull together all the results of my experiments to pick the best solution for each part of the design, regardless of cost and ease of building. The result is a "no compromise" design that has taken me a long time to make. Hopefully it will be reliable so that I can move on to exploring other things.

The design criteria for an extruder for HydraRaptor are a bit different from Darwin. The weight of the extruder is far less important because it is a moving table machine (rather than moving head). The z-axis is a big slab of aluminium so I don't need a heatsink or fan, I can just conduct the heat away.

I found that the best form of traction is a "worm pulley". Screw drive has slightly more grip on softer plastic but is far less mechanically efficient. It also has the nasty habit of making the feedstock rotate in some cases and also generates dust.

The pulley can impart in excess of 100N force on the filament before it slips, so to have the grip as the limiting factor we need a motor that can provide that amount of torque. The pulley has a radius of 6.5mm so that equates to 0.65Nm. I could do that with direct drive off a NEMA23, but even with micro stepping a single step is quite a lot of filament: 13mm × π / (200 × 8) = 0.025mm. That doesn't seem much but 0.5mm filament comes out 36 times faster than its 3mm feedstock goes in, so that is almost 1mm extruded per step. That seems way too big for accurate control to me, so some gearing is necessary.

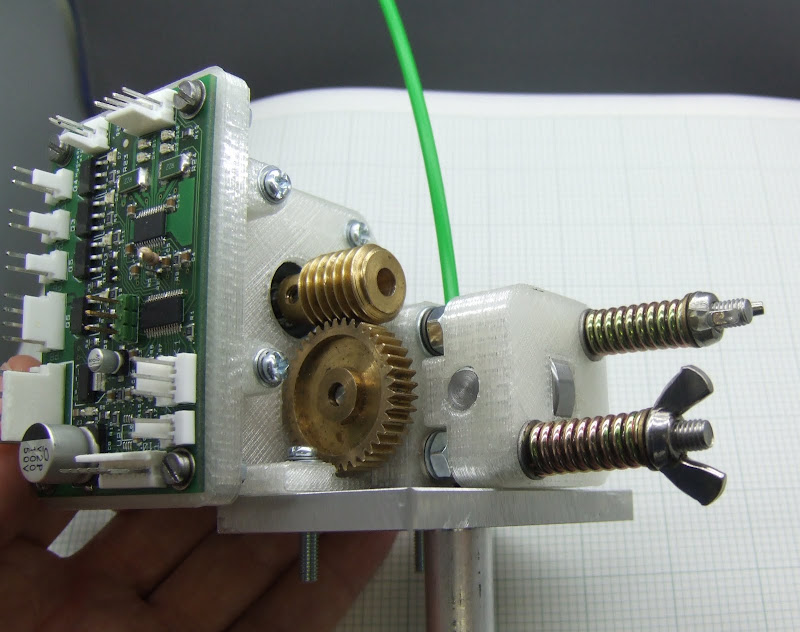

A worm gear is attractive because it gives a big reduction in one step so I came up with this arrangement: -

The pulley is on a 4mm splined shaft supported by two ball bearings. The gears are Meccano gears which are readily available. I couldn't find any other metal gears at reasonable prices. I had to drill out the worm wheel to fit the motor shaft. I filed flats on both shafts to allow the grub screws to grip.

This bearing cover holds the bearings in place and guides the filament: -

The assembly is clamped together by M5 hex head bolts that are captive in the plastic.

You can see the top of the stainless steel pipe that the filament feeds into. It has an aluminium outer sleeve to conduct the heat away from the transition section, rather than a heatsink. More on that later.

A skate bearing is used as a roller to apply pressure to the filament: -

A piece of M8 studding forms the axle. It is held in place just by friction. The bearing is centralised by cheeks on the plastic which are clear of the moving part.

The pressure is applied by springs and M5 wingnuts: -

The nuts on the bearing cover prevent the roller from meeting the drive pulley when there is no filament. That allows filament to self feed easily simply by inserting it into the hole in the top.

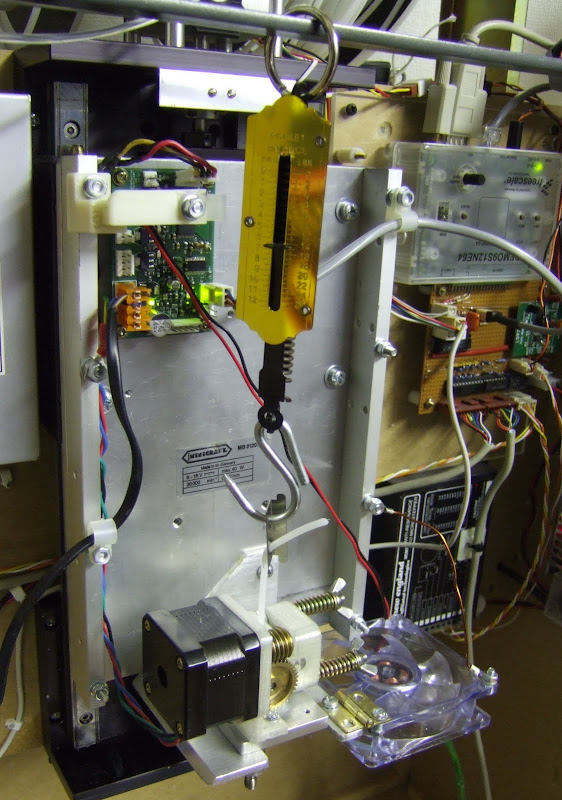

I measured the performance by attaching a spring balance to the filament and measuring the force at which the motor stalled for a given current: -

The motor is a NEMA17 rated at 0.3Nm holding torque with two coils on at 2.5A. The reduction ratio is 40:1, so I expected to only need about 0.637 / 40 to give a 100Nm pull. I was disappointed to find that I needed 1.5A to pull 10Kg.

With sinusoidal micro stepping drive the holding torque will be 0.7 times the two coil on value. I.e. 0.21Nm @ 2.5A, so 0.126Nm @ 1.5A. The torque from the pulley is only 0.016Nm assuming a reduction of 40:1, so the worm drive is only about 13% efficient if I have got my calculations right. Before I greased it, it was only half as efficient, so worm gears certainly waste a lot of effort in friction. The article here says they are between 98% and 20% for ratios 5:1 to 75:1, so I am probably in the right ball park. There will also be some friction in the bearings and pull out torque will be a bit less than holding torque, even though it is only rotating slowly.

So it reaches the target torque but with far less efficiency than my version with the tiny motor and the GM17 gearbox.

The other disappointment is that is is quite noisy, even when micro-stepping. That is simply because the z-axis couples any vibration to the wooden box behind it that then amplifies it. I

am tempted to fill it with something to dampen it down.

So this half of the extruder seems to perform, and it should be reliable because there is not much to wear out, except perhaps the worm gears, that is where most of the friction is and they are only made of brass.

I will test the bottom half of the design tomorrow.