The minimum quantity that I could buy was 1Kg, which cost aver £100 including shipping and VAT. You only need a couple of grams to make an extruder heater so it is actually cheaper than things like J-B Weld.

It is labeled as a hazardous substance and comes with a material safety data sheet which says it can't be disposed of in domestic waste and must not enter the sewage system. The hazardous components are identified as potassium silicate and sodium fluorosilicate. When I looked them up on the web I found that the former is added to growing medium and in cosmetics and the latter is one of the chemicals added to water for fluoridation. So they don't seem very hazardous but I suppose it's a matter of concentration.

I am assuming that once it has been cured, by the addition of a little water, that it is then no more hazardous that a ceramic potted resistor like this :-

We are no longer allowed to put electronics in domestic waste in the UK but you can just take it to the local tip.

I masked a brass heater barrel and applied a thin layer.

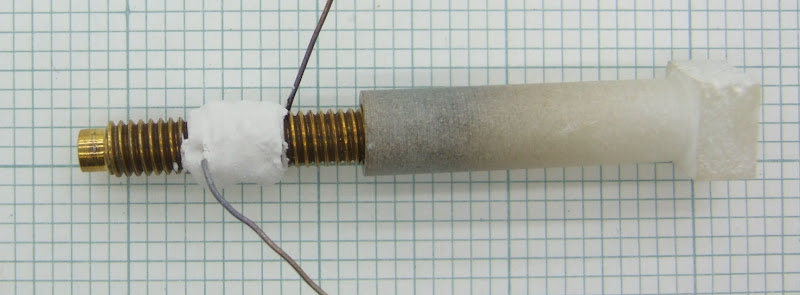

I left it to set for 24 hours and then wound it with two strands of 0.1mm nichrome twisted together. That gives me just 110mm for 8Ω, to keep the heater short. I attached copper wires with high temperature solder and then put a thicker layer of Cerastil over the top. I then left it another 24 hours to cure.

It looks a bit lumpy because of the solder joints underneath.

I mounted it in an insulator that I turned from soapstone and ran it for a few hours at ~290°C.

The bottom of the soapstone barrel got to about 120°C. After the test the Cerastil looked exactly the same, unlike J-B Weld which goes very dark. The soapstone did discolour though at the hot end.

So where has this experiment taken me on my quest to make a durable extruder that covers the full range of thermoplastics? Well I will definitely be using Cerastil from now on as it seems the perfect adhesive for potting heaters, not surprisingly as that is what it is designed for. It is a high temperature adhesive that is a good electrical insulator and a good thermal conductor. I am not sure I can recommend it for the RepRap project though because it is very specialist and not widely available

I am also not sure about the soapstone. I was surprised it changed colour but I don't know if it matters or not. It looks like it would need to be twice as long, or have a heatsink at the cool end. I am also a bit worried about its strength.