The thinnest practical wall you can print, (with Skeinforge at least), is two extrusion widths wide. Any bigger leaves a gap, until you get to three extrusions wide, and then you get infill in between them.

If the wall is exactly two extrusions wide then they only touch

tangentially and have a weak bond because the edges of the filament are

rounded.

I discovered that if you make a wall even thinner then Skeinforge still lays down two paths equal to the extrusion width but places them closer together. This is because it always offsets inwards by half the extrusion width, even if the resulting paths overlap. I found I can make use of this to squash the plastic together, making a stronger wall with less voids.

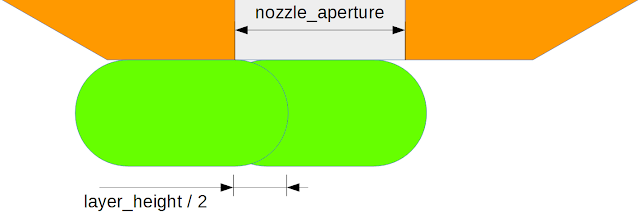

An optimum amount of squeeze is to place the nozzle aperture just free of the flat part of the first path when extruding the second. The width to make this happen is $extrusion\_width - layer\_height / 2 + nozzle\_aperture / 2 + extrusion\_width / 2$.

Of course, despite what Skeinforge thinks, the plastic volume can't overlap, so regardless of where the nozzle is the minimum width the wall can be is $2 * extrusion\_width - layer\_height * (1 - π/4)$ due to the volume of plastic extruded, i.e. if it manages to completely fill the voids. This is shown below: -

The grey area is where the edge would have been with the wall two extrusion widths wide. There isn't much difference, and depending on the viscosity of the plastic, the real width should be somewhere in between. But the big difference is the walls are strongly fused together. The top void should be completely filled because it is right under the nozzle, leading to a smoother top surface. And the bottom void has more chance of being filled due to the back pressure caused by the filament having to flow more to the right.

To put some numbers to the diagrams, these have been drawn to scale for 0.25mm layer height and 0.5mm extrusion width, 0.4mm nozzle. The requested wall width is 0.825mm but the volume of plastic means it must be at least 0.946mm, only 0.054mm less than the original 1mm wall.

I made a test script that makes a box with two 1mm walls and two 0.825mm walls.

Here is a corner of the box under a microscope. The wall on the left is seamlessly fused and the wall on the right clearly has a void.

The wall comes out a bit thinner than the theory predicts, I am not sure why, maybe the increased pressure causes the plastic to feed a bit slower.

I used this technique to make the Mendel90 fan guards a lot stronger part way through production because I had some fall apart one day when my filament was a bit undersized.

It would be nice if the slicer could do this automatically, so you can keep a 1mm wall in the design, but it would make it by extruding one side of the wall as normal but the other side it would offset the nozzle to fill the voids and then extrude a little more plastic to make it still 1mm thick.

In fact it should really do this anytime it is extruding against another extrusion path. E.g. when doing multiple outlines and when doing infill. I.e. the only time the tool path of the nozzle should be down the centre of the extrusion path is when there is nothing either side, or it is enclosed on both sides. And in each of these three cases a slightly different flow rate would be needed to get the new exposed edge in the correct place.

Tuesday, 3 April 2018

Subscribe to:

Post Comments (Atom)

Glad to see you're posting again. I've always followed your blog in the shadows but it's time to lay down a msg to let you know that you're an inspiration to me, I love your methodic approach to solve problems, and I hope some day to be at least half as good as you as engineer.

ReplyDeleteI'm the owner of a self sourced mendel90, that was the only printer I didn't dismantle to take parts because is one of the sturdiest and most reliable printers I own.

Sorry about my english.

Cheers from Argentina!!

Nicolas.

Thanks, glad you like the Mendel90 design.

Delete