Bearings

With the stainless steel bars that I use I found that PLA bushings only last a few hundred hours before they wear out. I tried Igus plastic bushings and they only lasted about the same length of time. I think you need ground rods rather than rolled to get a smooth enough surface for bushings. Possibly the lithium grease that I used was not suitable for plastic as I am sure other people must have got better life out of bushings.

The ball bearings on my Mendel have proved very durable but they do wear flats on the rods after about a year of continuous use. This wouldn't be a problem except that the rods wear more in the middle, which leads to inconsistent Z height eventually. You can turn the rods to put the flats underneath and get many more years life.

I have run some LM10UU bearings for over a year non-stop and they have not worn the rods noticeably. I did have an LM8UU bearing suddenly decide it only wanted to go one way on my Prusa's X-axis. It just needed some oil to make it work again. I think the X-axis tends to dry out because it runs over the heated bed.

I made the Mendel90 prototype with 10mm rods because I had noticed the 8mm rods sag a little on my Mendel, that has a heavier bed and extruder though. 10mm rods cost quite a lot more than 8mm and the plastic parts get bigger so I intend to make an 8mm version and see how it compares.

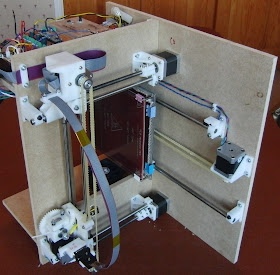

X-Axis

The X axis is similar to the Prusa but I have changed a few things: -

Note the axis is shortened in this picture, the belt has a twist not shown and a loop round the tensioning screw.

I lowered the idler and the motor to be in line with the bars because I noticed on my Prusa that the belt tension tended to bow the bars upwards slightly at the ends. It does mean the belt is a bit closer to the heated bed but I haven't noticed any ill effects.

I swapped the positions of the Z bars and Z leadscrews so that the bearing holders face inwards. That means the belt tension tends to push the bearings into their holders rather than pulling them out. That allowed me to get rid of the cable ties.

There are clamps for the X-bars so they don't have to be exactly the right length. They can be adjusted a few mm lengthwise and then locked in place. The holes are open ended at the idler end to allow the bars to be removed without removing the Z-bars first.

The motor housing is a box shape to keep it rigid while still having only relatively thin walls. The hole in the top is for the wires and lets any heat out.

I didn't use a 608 skate bearing for the idler. They might be cheap and available world wide but I found they didn't work on my Prusa, whereas the 624 bearings used on the Sell's Mendel do work. Ball bearings have a chamfered edge, the bigger the bearing the bigger the chamfer and M8 washers are thicker than M4 washers. With 8mm bearings that leaves a gap big enough for the belt to ride down and bind, whereas with 4mm bearings the gap is much smaller so the belt simply brushes against the penny washer, rather than jamming.

I prefer a bearing to a printed pulley with flanges or a crown pulley because if I am using a metal drive pulley for accuracy it does not make sense to have a printed idler.

I haven't added it to the model yet, but there is a half twist in the long return path of the belt so that the smooth side goes over the idler, not the teeth, to avoid any cogging. The twist in the belt doesn't seem to cause any problems, if it did I could revert to the technique here: hydraraptor.blogspot.com/2011/06/half-belt-hack

The belt tensioning is as Greg Frost's design: The ends of the belt are locked in place by clamps with mating teeth. A screw tightens a Nyloc nut against a loop of the belt.

The carriage is the full size of the extruder with the bearings optimally placed in a triangle and the belt attached at the ends. It does mean the carriage is a bit bigger than most but it makes best use of the space to achieve stability. I.e. the travel is limited by the extruder, so there is no point making the carriage smaller, other than reducing print time.

The carriage follows the rod on the two bearing side and only needs to be prevented from rotating around it by the third bearing. In order not to be over constrained the third bearing is suspended by thin but tall struts. That allows it to float horizontally but it is constrained vertically. This prevents binding in the event of the rods being slightly miss-aligned.

The underside of the carriage is shelled and ribbed to save print time but keep it rigid. That has been my philosophy on the design, strength through complexity of shape rather than chunkiness. Whereas other people have tried to reduce the printed parts to a minimum I have tried to put functionally first.

I found that I could not make bearing clamps in the horizontal direction with enough grip so I use cable ties as well on these. The bearings rest at each, end so a single tie in the middle is sufficient to keep them stable.

Y-Axis

The Y axis sits on a flat sheet ensuring the bars lie in the same plane. Only three bearings are needed so the rod on one side can be shorter as it no longer needs to attach at the very front and back. The X-axis also uses three bearings and Z four, making the total ten, which is convenient as they tend to be sold in packs of ten. The belt is also shorter because the motor and idler can be brought inside the axis travel.

The Y motor bracket is a lot more rigid than the Prusa version due to its boxy shape and being screwed to the base instead of hung from bars. The bar clamps are also hollow boxes.

The bearing holders are the same as the ones on the carriage using tie wraps .

Alignment is easy, all the bar clamps and bearing clamps have slotted screw holes allowing a little side to side movement. Initially all the screws are left loose. The long bar is set at right angles to the gantry using a set square and then the bar clamp screws are tightened. The bearing clamps on that side are then tightened. The y-carriage can then be moved backwards and forwards to pull the second bar into alignment before those are tightened. On my todo list is to float the third bearing like I have done on the carriage.

Again the belt has a half twist in the lower return path, not shown on the model. Belt tensioning is easy because the idler has a slot to allow it to be adjusted. The single mounting hole also allows the angle to be adjusted to centre the belt. I plan to move it to the front and put the motor at the back as it makes the wiring shorter and the idler adjustment more accessible. I used two 624 bearings side by side to allow the belt to wander a bit without binding. I seemed to need that on Y but not X. I may move to two on the X-axis as well to give a completely frictionless arrangement.

If you are wondering what the two large holes in the base are, they are there so that dual shaft motors can be used.

Z-Axis

I moved the motors to the bottom to eliminate the possibility of the couplers slipping off. I made the couplers as skinny as possible to get the bar close to the lead screw. That makes the X ends smaller and allows the Z bar to rest on top of the motor giving a metal connection from the base to the top limit switch minimising the effect of the wood shrinking and expanding. For normal Reprap software it probably needs an adjustable bottom limit switch instead.

Note the axis is shortened in this picture.

The Z bars are automatically parallel to the gantry because the distance at the top and the bottom is set by printed parts. The bar clamps at each end of the rods are identical allowing the axis to be made vertical with a set square. This is done at the left hand side and the other side is made parallel by moving the axis up and down before tightening the screws.

I kept the facility for anti-backlash nuts and springs but the only machine I needed to fit them on was my Prusa. I am not sure why, but even the weight of an extra motor was not enough to overcome the backlash with gravity. I think it must have either been due to binding or perhaps the grease I used was thick enough to need some force to squeeze it out of the way. I needed stiff springs and I had to turn up the z-motor current after fitting them. The advantage of not fitting them is it gives some protection against a head crash as the maximum force you can apply downwards is the weight of the X-axis and extruder.

I considered using a single motor and linking the screws with bevel gears and a drive shaft. That would be cheaper than a second motor or a belt but I stuck with two motors for simplicity at the moment.

Bed

I have previously used 6mm aluminium tooling plate with aluminium clad power resistors for my heated beds. These work well but they are heavy. The Prusa PCB heater with a 2mm glass sheet on the top makes a much lighter solution. The picture above shows it clamped down with penny washers but bulldog paper clips work better.

I use 3mm Dibond for the Y-carriage because it is light, stiff and stable. I tried 6mm MDF on my Prusa but it warped due to the heat and the bed never stayed level for long. I don't know how other people manage to use it.

The best bed mounting solution I have tried so far is 20mm brass hex pillars. I tap the carriage holes M3 and screw the pillars into it. I can then level the bed by adjusting them and use the screw in the top to lock the position. I don't like to use springs because they let the bed wobble.

To level the bed I put M3 washers under the back two pillars and screw them tight and lock them. I then twist the Z motors by hand to make both sides level at the back relative to the nozzle. I then adjust the front two pillars to get the bed level front to back.

The process is easy but tedious because all the adjustments interact to some extent, so you have to keep going round them. It would be better if the bed had a single mounting hole at the front in the middle, as you only need one adjustment to get the bed level from front to back. I need to make a smaller version of my Z-probe so I can auto level the bed.

I like to use an air gap under the bed for insulation so that I can cool it rapidly with a fan at the end of the build to make the parts release easier. The air gap provides enough insulation but the Dibond below still gets to around 50°C. I added a heat shield made from corrugated cardboard covered in aluminium foil tape and the Dibond no longer gets warm at all.

The slots are to clear the screw heads. I stuck it down with double sided tape but that did not hold so I added bulldog clips. If I was making another I would bolt it down.

I haven't made any measurements yet but I think the difference in temperature between the middle and the edges is bigger than my aluminium beds. I Intend to try adding printed baffles at the front and the back to stop the movement of the bed pushing cold air under it.

I think I can improve the temperature distribution by changing the PCB pattern. The problem at the moment is that if the middle runs a bit hotter then the tracks local to it will have a higher resistance than those at the edges, which are connected in series with it. That means the middle will get more voltage and become even hotter relative to the edges, positive feedback. A better arrangement would be to have concentric rings of tracks running through areas that are likely to be the same temperature, wired in parallel. That way if the middle got hotter it would only have tracks near the middle in its circuit, so the increase in resistance would lower the current and give some negative feedback.

Another thing I would change would be to remove the silk screen from the top layer as it has some thickness that will reduce the thermal contact with the glass.

Cables

Larger CNC machines use cable chains to enforce a minimum bend radius on moving cables to stop them breaking. There have been several printable versions on Thingiverse but I feel they would give more friction than desirable for a small machine like this. Ribbon cables are very flexible in one direction and are surprisingly rated for 300V, 1.4A and 105°C.

For the heated bed I use ten wires in each direction plus 2 for the thermistor. I clamp it at both ends with a thin strip of polypropylene about 0.5mm thick. That forms the equivalent of a miniature cable chain but with very low friction. Here is the one under the bed: -

This one feeds the X motor and the extruder: -

The rest of the wiring is done on the back of the gantry with printed cable clips : -

The fan on the left is a powerful 80 CFM fan that I use to cool the bed from 110°C to 30°C in about 6 minutes.

The only down side of ribbon cable is that you get some inductive cross talk from the motor signals to the endstops. That doesn't affect my firmware as I only read the endstops during homing and a simple retry loop sorts that out. For firmwares that constantly monitor the endstops a simple RC filter on the inputs should fix it.

This version of the machine I call the Sturdy model. It uses 10mm rods, M4 fasteners and has a build area slightly bigger than a Mendel: 214 x 214 x 150mm. The next version I try will use 8mm rods, M3 fasteners and have an acrylic frame. I will reduce the build area to 200 x 200 x 140mm, same as Mendel so it will be more of an equivalent. I will also make a Huxley equivalent with NEMA14 motors and 6mm rods. The Mendel sized variant will cost a bit less but I doubt the Huxley will be any cheaper.

The ball bearings on my Mendel have proved very durable but they do wear flats on the rods after about a year of continuous use. This wouldn't be a problem except that the rods wear more in the middle, which leads to inconsistent Z height eventually. You can turn the rods to put the flats underneath and get many more years life.

I have run some LM10UU bearings for over a year non-stop and they have not worn the rods noticeably. I did have an LM8UU bearing suddenly decide it only wanted to go one way on my Prusa's X-axis. It just needed some oil to make it work again. I think the X-axis tends to dry out because it runs over the heated bed.

I made the Mendel90 prototype with 10mm rods because I had noticed the 8mm rods sag a little on my Mendel, that has a heavier bed and extruder though. 10mm rods cost quite a lot more than 8mm and the plastic parts get bigger so I intend to make an 8mm version and see how it compares.

X-Axis

The X axis is similar to the Prusa but I have changed a few things: -

Note the axis is shortened in this picture, the belt has a twist not shown and a loop round the tensioning screw.

I lowered the idler and the motor to be in line with the bars because I noticed on my Prusa that the belt tension tended to bow the bars upwards slightly at the ends. It does mean the belt is a bit closer to the heated bed but I haven't noticed any ill effects.

I swapped the positions of the Z bars and Z leadscrews so that the bearing holders face inwards. That means the belt tension tends to push the bearings into their holders rather than pulling them out. That allowed me to get rid of the cable ties.

There are clamps for the X-bars so they don't have to be exactly the right length. They can be adjusted a few mm lengthwise and then locked in place. The holes are open ended at the idler end to allow the bars to be removed without removing the Z-bars first.

The motor housing is a box shape to keep it rigid while still having only relatively thin walls. The hole in the top is for the wires and lets any heat out.

I didn't use a 608 skate bearing for the idler. They might be cheap and available world wide but I found they didn't work on my Prusa, whereas the 624 bearings used on the Sell's Mendel do work. Ball bearings have a chamfered edge, the bigger the bearing the bigger the chamfer and M8 washers are thicker than M4 washers. With 8mm bearings that leaves a gap big enough for the belt to ride down and bind, whereas with 4mm bearings the gap is much smaller so the belt simply brushes against the penny washer, rather than jamming.

I prefer a bearing to a printed pulley with flanges or a crown pulley because if I am using a metal drive pulley for accuracy it does not make sense to have a printed idler.

I haven't added it to the model yet, but there is a half twist in the long return path of the belt so that the smooth side goes over the idler, not the teeth, to avoid any cogging. The twist in the belt doesn't seem to cause any problems, if it did I could revert to the technique here: hydraraptor.blogspot.com/2011/06/half-belt-hack

The belt tensioning is as Greg Frost's design: The ends of the belt are locked in place by clamps with mating teeth. A screw tightens a Nyloc nut against a loop of the belt.

The carriage is the full size of the extruder with the bearings optimally placed in a triangle and the belt attached at the ends. It does mean the carriage is a bit bigger than most but it makes best use of the space to achieve stability. I.e. the travel is limited by the extruder, so there is no point making the carriage smaller, other than reducing print time.

The carriage follows the rod on the two bearing side and only needs to be prevented from rotating around it by the third bearing. In order not to be over constrained the third bearing is suspended by thin but tall struts. That allows it to float horizontally but it is constrained vertically. This prevents binding in the event of the rods being slightly miss-aligned.

The underside of the carriage is shelled and ribbed to save print time but keep it rigid. That has been my philosophy on the design, strength through complexity of shape rather than chunkiness. Whereas other people have tried to reduce the printed parts to a minimum I have tried to put functionally first.

I found that I could not make bearing clamps in the horizontal direction with enough grip so I use cable ties as well on these. The bearings rest at each, end so a single tie in the middle is sufficient to keep them stable.

Y-Axis

The Y axis sits on a flat sheet ensuring the bars lie in the same plane. Only three bearings are needed so the rod on one side can be shorter as it no longer needs to attach at the very front and back. The X-axis also uses three bearings and Z four, making the total ten, which is convenient as they tend to be sold in packs of ten. The belt is also shorter because the motor and idler can be brought inside the axis travel.

The Y motor bracket is a lot more rigid than the Prusa version due to its boxy shape and being screwed to the base instead of hung from bars. The bar clamps are also hollow boxes.

The bearing holders are the same as the ones on the carriage using tie wraps .

Alignment is easy, all the bar clamps and bearing clamps have slotted screw holes allowing a little side to side movement. Initially all the screws are left loose. The long bar is set at right angles to the gantry using a set square and then the bar clamp screws are tightened. The bearing clamps on that side are then tightened. The y-carriage can then be moved backwards and forwards to pull the second bar into alignment before those are tightened. On my todo list is to float the third bearing like I have done on the carriage.

Again the belt has a half twist in the lower return path, not shown on the model. Belt tensioning is easy because the idler has a slot to allow it to be adjusted. The single mounting hole also allows the angle to be adjusted to centre the belt. I plan to move it to the front and put the motor at the back as it makes the wiring shorter and the idler adjustment more accessible. I used two 624 bearings side by side to allow the belt to wander a bit without binding. I seemed to need that on Y but not X. I may move to two on the X-axis as well to give a completely frictionless arrangement.

If you are wondering what the two large holes in the base are, they are there so that dual shaft motors can be used.

Z-Axis

I moved the motors to the bottom to eliminate the possibility of the couplers slipping off. I made the couplers as skinny as possible to get the bar close to the lead screw. That makes the X ends smaller and allows the Z bar to rest on top of the motor giving a metal connection from the base to the top limit switch minimising the effect of the wood shrinking and expanding. For normal Reprap software it probably needs an adjustable bottom limit switch instead.

Note the axis is shortened in this picture.

The Z bars are automatically parallel to the gantry because the distance at the top and the bottom is set by printed parts. The bar clamps at each end of the rods are identical allowing the axis to be made vertical with a set square. This is done at the left hand side and the other side is made parallel by moving the axis up and down before tightening the screws.

I kept the facility for anti-backlash nuts and springs but the only machine I needed to fit them on was my Prusa. I am not sure why, but even the weight of an extra motor was not enough to overcome the backlash with gravity. I think it must have either been due to binding or perhaps the grease I used was thick enough to need some force to squeeze it out of the way. I needed stiff springs and I had to turn up the z-motor current after fitting them. The advantage of not fitting them is it gives some protection against a head crash as the maximum force you can apply downwards is the weight of the X-axis and extruder.

I considered using a single motor and linking the screws with bevel gears and a drive shaft. That would be cheaper than a second motor or a belt but I stuck with two motors for simplicity at the moment.

Bed

I have previously used 6mm aluminium tooling plate with aluminium clad power resistors for my heated beds. These work well but they are heavy. The Prusa PCB heater with a 2mm glass sheet on the top makes a much lighter solution. The picture above shows it clamped down with penny washers but bulldog paper clips work better.

I use 3mm Dibond for the Y-carriage because it is light, stiff and stable. I tried 6mm MDF on my Prusa but it warped due to the heat and the bed never stayed level for long. I don't know how other people manage to use it.

The best bed mounting solution I have tried so far is 20mm brass hex pillars. I tap the carriage holes M3 and screw the pillars into it. I can then level the bed by adjusting them and use the screw in the top to lock the position. I don't like to use springs because they let the bed wobble.

To level the bed I put M3 washers under the back two pillars and screw them tight and lock them. I then twist the Z motors by hand to make both sides level at the back relative to the nozzle. I then adjust the front two pillars to get the bed level front to back.

The process is easy but tedious because all the adjustments interact to some extent, so you have to keep going round them. It would be better if the bed had a single mounting hole at the front in the middle, as you only need one adjustment to get the bed level from front to back. I need to make a smaller version of my Z-probe so I can auto level the bed.

I like to use an air gap under the bed for insulation so that I can cool it rapidly with a fan at the end of the build to make the parts release easier. The air gap provides enough insulation but the Dibond below still gets to around 50°C. I added a heat shield made from corrugated cardboard covered in aluminium foil tape and the Dibond no longer gets warm at all.

I haven't made any measurements yet but I think the difference in temperature between the middle and the edges is bigger than my aluminium beds. I Intend to try adding printed baffles at the front and the back to stop the movement of the bed pushing cold air under it.

I think I can improve the temperature distribution by changing the PCB pattern. The problem at the moment is that if the middle runs a bit hotter then the tracks local to it will have a higher resistance than those at the edges, which are connected in series with it. That means the middle will get more voltage and become even hotter relative to the edges, positive feedback. A better arrangement would be to have concentric rings of tracks running through areas that are likely to be the same temperature, wired in parallel. That way if the middle got hotter it would only have tracks near the middle in its circuit, so the increase in resistance would lower the current and give some negative feedback.

Another thing I would change would be to remove the silk screen from the top layer as it has some thickness that will reduce the thermal contact with the glass.

Cables

Larger CNC machines use cable chains to enforce a minimum bend radius on moving cables to stop them breaking. There have been several printable versions on Thingiverse but I feel they would give more friction than desirable for a small machine like this. Ribbon cables are very flexible in one direction and are surprisingly rated for 300V, 1.4A and 105°C.

For the heated bed I use ten wires in each direction plus 2 for the thermistor. I clamp it at both ends with a thin strip of polypropylene about 0.5mm thick. That forms the equivalent of a miniature cable chain but with very low friction. Here is the one under the bed: -

This one feeds the X motor and the extruder: -

The rest of the wiring is done on the back of the gantry with printed cable clips : -

The fan on the left is a powerful 80 CFM fan that I use to cool the bed from 110°C to 30°C in about 6 minutes.

The only down side of ribbon cable is that you get some inductive cross talk from the motor signals to the endstops. That doesn't affect my firmware as I only read the endstops during homing and a simple retry loop sorts that out. For firmwares that constantly monitor the endstops a simple RC filter on the inputs should fix it.

This version of the machine I call the Sturdy model. It uses 10mm rods, M4 fasteners and has a build area slightly bigger than a Mendel: 214 x 214 x 150mm. The next version I try will use 8mm rods, M3 fasteners and have an acrylic frame. I will reduce the build area to 200 x 200 x 140mm, same as Mendel so it will be more of an equivalent. I will also make a Huxley equivalent with NEMA14 motors and 6mm rods. The Mendel sized variant will cost a bit less but I doubt the Huxley will be any cheaper.