The originals were made with the bed at 100°C, but the insulating effect of 4mm of PMMA gave a surface temperature of only~85°C. That was sufficient to form a partial weld strong enough to resist warping. My first test was with the bed at 100°C, but that came loose after a few layers. With the other plastics I have found I need a higher temperature on PI because it does not form a weld. It sticks by some magic that I don't understand, possibly Van de Waals forces.

I tried again with the bed at 130°C and this time it stuck well but was easily peel-able by bending the bed. So another plastic that works on hot polyimide.

I have also been doing multi-part builds one layer at a time, something I hadn't dared to do until recently because my previous extruders were not reliable enough to risk a bed full of objects.

If you get the height just right on the polyimide bed the first layer comes out almost perfect. You can actually make one layer thick objects, i.e. 0.3mm in this case.

These came out very well.

I arrange multiple items by reading the STLs into AOI and orienting and positioning them. I then union them together in pairs and then union all the unions until I have a single object. I then convert that to a triangle mesh and export it as a GTS. If I don't convert first I only get one object in the GTS rather than the composite. I then slice as one object.

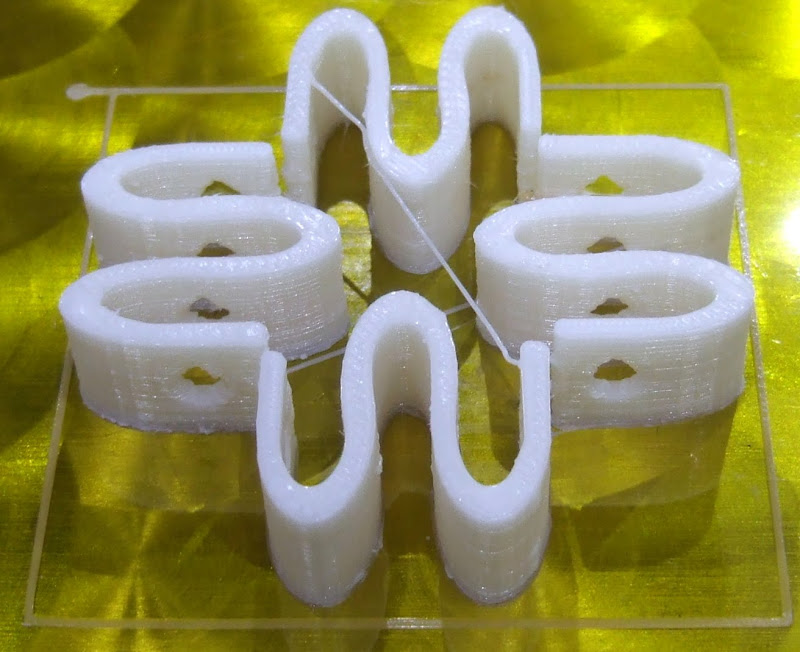

These springs show a very rare bug in Skeinforge or my code where it does a move with the extruder on. That is the only time I get any string.

Here is an assortment of smaller parts :-

It is best to group the taller parts together so when it gets to the higher layers the head does not have far to travel.

There were so many in this build that it overlapped the hot part of the table, so a few corners lifted a bit. I think ideally the table should be a bit bigger than the movement to keep some warm air around the objects. Perhaps a wall around the edge would keep some heat in.

I did have the crazy idea of building a wall around the objects as they are made so that there is a small gap of trapped hot air around them. I.e. the machine builds a disposable cocoon around the object to act as a heated build chamber. It would be a bit wasteful of plastic of course but it could be made from a cheap paste if we had a second head.

Where do you get the Kapton sheet from? I searched through your previous posts but could only find reference to Kapton tape.

ReplyDeleteA friend gave me some samples of film, not sure where he got them. The stuff in the pictures is 150mm wide tape though, stuck onto 0.3mm steel. That works better than the film on the vacuum table.

ReplyDeleteYou posts continue to amaze and inspire me. The quality of prints looks just fantastic. I just ordered a heating element from Omega to build a heated bed for the machine I'm building here:

ReplyDeletehttp://multi-bot.blogspot.com

Again, you were faster than me:-(

ReplyDeleteLaszlo

these objects look stunning! You're definitely one of the leading innovators of the reprap community.

ReplyDeleteWow .. damn.. thinking you only live up the road from us.. Just hope I can get this kind of result..

ReplyDeleteYet again the pictures and the printing is stunning.

you asked If I needed anything.. for the show If you have any Junk bits in the recycling box I can borrow for the show that would be great. Midge could mount them on some mount board.

and any Video files I can put on CD as I don't know how good my Internet connection will be at the show.

In fact if any one has good quality RepRap Video files I can use for projection please let me know. I have no idea if you can grab files of YouTube or if its legal to do that so Only files that you own the rights to please.

PS. KiCad is great thanks for your advice!

I am having good success with ABS printed parts on Plasticard from the local model shop taped with double sided tape to my heated bed at around 60 degrees. The parts peel easily and don't warp.

ReplyDelete@Bodgeit,

ReplyDeletePM sent.

@Anon,

Interesting. How thick is the plasticard? How reusable is it?

I used 0.4mm but I'm looking to get the thickest possible as it pinches a little at the edges if you take the bed over 60 degrees. I have reused the same piece about 10 times now and its still OK. It works quite well without the heated bed.

ReplyDeleteMartin

really great work. how long are some of these multi=part prints taking?

ReplyDeleteI think the biggest was 4.5 hours. It could be quicker because I am using 0.375mm filament but most parts would be just as good with 0.5 or 0.6mm.

ReplyDeleteDamn, those look good. :-D

ReplyDeleteThis is amazing. I love the idea of mult-part printing. Just curious, but do you think it's possible to do water-soluble support material? That way, you could build up instead of on separate trays. I don't know about having to do a raft in mid-air, but it would be interesting. I was thinking a pure infrastructure around the parts would work, but then again, it might not. Can you test that?

ReplyDeletePVOH has been suggested many times for a water soluble support. I have never seen it available as a filament though so can't try it.

ReplyDeleteI plan to use PLA to support ABS and dissolve it with caustic soda.

It would be possible to build rafts over the top of objects but it would waste a lot of plastic and because it is not heated objects would warp. I prefer not to use rafts at all these days.

You don't seem to need them. That bottom layer of the reprap part is perfectly flat. Do you have enough parts to build a spare mendel?

ReplyDeleteI don't need a raft because the bed is heated to the melting point of the plastic. If I build something up in the air it would warp as it is cooler and has nothing underneath to hold it down.

ReplyDeleteI have made a full set of Mendel parts and I am putting it together now.

Hi

ReplyDeleteI just completed reading your blog from day 1 and till today, and I want to thank you for your huge effort, highly disciplined and well documented posts. By reading this I feel that I have come to a good understanding of - atleast some - the requirements of a good extruder.

The only thing remaining for me to do, is to figure out how to make your "no compromize extruder" with the tools I have in hand.

dude!

ReplyDelete2 weeks w/o a post and you know whats gonna happen! the sweed is gonna start whining... now dont blame the olymic games, i know that that youwe been printing stuff!!

//sweden

I finished printing my Mendel and am now cutting up rods, etc, to put it together. So nothing to post until it is finished. I did print one of these: http://www.thingiverse.com/derivative:1643 and assembled two more of these: http://www.thingiverse.com/derivative:1644 and a couple of these: http://hydraraptor.blogspot.com/2009/08/time-for-new-extruder-controller.html so been busy.

ReplyDeleteNopHead, could you please tell me the name of the music fro you video with title "Spanning a void"?? -- I would really like to know who is author, as I am now always listening that music while setup my EMCRepStrap to print pieces for my future Mendel :-)

ReplyDeleteWatch the credits at the end.

ReplyDeleteOh, thanks! I hate to "pirate" music and I prefer CC music, and luckily that author let us download his music freely: http://nsf.4x86.com/?p=music

ReplyDeleteNopHead, will you start using Mendel? if so, why? I think you have a better printer than Mendel(looking at your print quality), right?

I plan to use my Mendel to make parts and sell them. I will run it continuously and still have HydraRaptor for research. It should be a lot faster than HydraRaptor and has a bigger build area. Also, if anything wears out I can replace it, which is not true for HydraRaptor.

ReplyDeleteI don't see why the quality should be noticeably worse if I use a geared extruder and my firmware. I plan to use a bigger nozzle for churning out the larger Mendel parts.

I am hoping that your work get in RepRap, in some way I think he is already influencing others :-)

ReplyDeleteI am very happy to know that you are going with a Mendel. Me too, but because my code for my EMCRepStrap will never be so good as FiveD... I need to use Mendel, it's the only way where I can access the best technology for 3D printing :-)

I am looking for FiveD to have acceleration on XY and so get higher print velocities! Also FiveD/Skeinforge have the extruder reverse functionality as you have on your custom firmware :-)

I don't have a lot of faith in 5D because Triffid_hunter has said it uses exponential acceleration which is the opposite of what a stepper likes. I use a much simple scheme with linear acceleration.

ReplyDeleteThe other problem is that it ramps the extruder speed in step with the axes, but the extruder is a low pass filter so should have a different acceleration profile.

Currently I have very short acceleration and the fastest stop and start that I can get on the extruder.

In the future I plan to chose an acceleration profile that matches the axes movement to the extruder output, not its input.

Ok, so I have a lot yet to learn about Mendel.

ReplyDelete"In the future I plan to chose an acceleration profile that matches the axes movement to the extruder output, not its input." --> but will you have any feedback from output? or you plan to go with experimentation?

Your prints looks like perfect now, so you are aiming even better? do you think they can be even better?

There are no strings any more, but there are a few blobs where the filament starts and stops. More so with ABS than PLA I think. The reason is that when you fast forward to where you pulled back from you create the same pressure as the normal extrusion pressure, so the flow rate is correct at the end of the fast forward. But during the fast forward some filament will start to extrude as the pressure builds up, so the axes should start to move off at a speed that matches that flow.

ReplyDeleteBefore I try that complexity I will try to hide the blob on the inside like Adrian does.

No I don't plan any feed back. I will use a mathematical model or an RC filter and try to find the time constant be trial and error.

ReplyDeleteCommon dude!

ReplyDeleteAnother week without a post!

If you cannot publish the big "do you want to come home and look at my mendel?"-post, do some sort of sneak preview! a kind of in-between post! (i think that your loyal followers can demand to get at least a two posts a week minimum!

over and out

Sweden

I agree, at least 1 post a week ;-)

ReplyDeleteYes, I really want a post about the Mendel! Thanks!

ReplyDeleteplease

ReplyDeleteWake up dude! We can not handel this absence..

ReplyDeleteEveryone who supports the 2 posts per week policy +1 on this msg!

+1!

ReplyDeleteBTW: A question: everyone seems to want mendel parts... is self-replication really the best way to go here? I realize that this is like cursing in church but: some sort of mold and then produce many of them at a faster pace?

Nice where it works, but not everything can be molded.. how would you make a mold for a corner component with holes through three axes. FDM (at least with support material) can theoretically make any shape.

ReplyDelete