- If the shaft position gets more than, say, half a turn behind then give up.

- If the thermistor resistance is too high then the thermistor is open circuit so turn the heater off.

- If the thermistor resistance is too low then the thermistor is short circuit.

- If the heater has been on for more than 5 seconds and the temperature has not risen then the heater is open circuit.

- If the heater has been off for 5 seconds and the temperature has not dropped then panic, the transistor is short circuit.

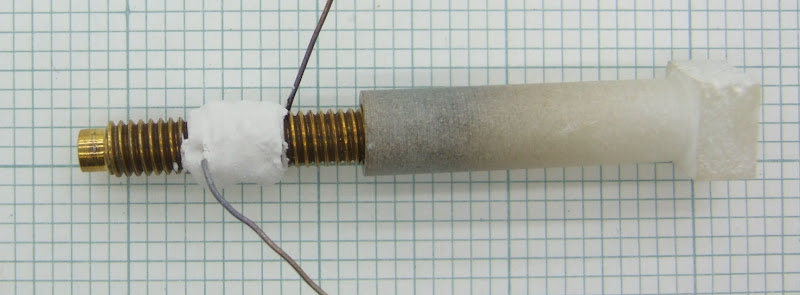

The solution to the code wheel problem was to extend the shaft of the GM3 with a piece of brass rod :-

I have managed to perform quite a lot of tests with HDPE and it is clear that the new acorn nut nozzle behaves quite differently to the previous one piece design.

The original nozzle looked like this and had a 0.5mm hole that was about 0.6mm deep: -

The new nozzle is made from an acorn nut turned to a point. I also has a 0.5mm hole, but it is tapered at about 45° so the the part of the hole that is 0.5mm diameter is very thin :-

The differences this seems to make are: -

- The die swell, i.e. the amount the filament expands from the hole diameter, is a little less.

- The amount of filament that extrudes after the motor is switched off has increased quite a lot. The excess is wiped from the nozzle, but by the time the head has moved from the brush back to the workpiece, a few more mm have leaked out making for a messy line start. I think this is because the shorter exit hole makes it easier for the plastic to escape.

- If I move the head quickly with the extruder off, then the filament snaps. It quite often leaves a blob that sticks to the workpiece. With the longer hole it stretched to a long thin string rather than snapping.

- I used to be able to lay down 0.5mm filament at 16mm/s by stretching, but now I can only do this reliably at 8mm/s as the filament has a tendency to snap. I think it is too easy to pull it from the new shaped hole.

I can't run the fan because the heat loss from the bigger nozzle causes the heater to work harder, raising the temperature of the barrel above the point where the PTFE distorts. I need to insulate the nozzle so I will try making a new one similar to this one with a PTFE cover over it.

Here is about where I am at with extrusion quality: -

This is a rectangular block about the size of the extruder pump (60 x 20 x 15mm), with a 50% fill. I forgot to put a top surface on it but that is perfectly possible. It was extruded at 220°C (measured at the nozzle) with filament stretched to 0.75mm at 7mm/s. The layer height is 0.6mm and the pitch is 0.9mm. Some warping still evident but it has come a long way from my first attempts.