Skeinforge

I slice everything I print with Skeinforge, so the normal Mendel90 parts are designed around its limitations. It normally does a good job of detecting bridges and aligning the infill to span the gap. Its big limitation is that it does the infill for an entire layer in one direction, whereas it should at least be per island. However, even with the original flat fan duct it doesn't see the first layer of the roof as a bridge.Left to its own devices it does this for the bridging layer.

Layer before roof: -

First bridging layer: -

Clearly this doesn't print well because the ends of the infill don't land on anything. The orange section of infill has nothing under the yellow internal edge, so the loops just fall down.

Filament runs can't start, end or change direction when there is nothing under them, whether it be infill or outline. I don't know what algorithms slicers use but if I was writing one I would generate the infill for an island at the default angle and then check that all the end points land on something below. If not then I would try aligning it with each of the straight sides of the outline, starting with the longest first, noting how many endpoints miss. In most cases that would yield a direction with no misses. In the unlikely event it didn't then I would go for the direction with least misses and try reducing them by tweaking the angle. If there is no solution then I would issue a warning and miss out the lines that can't be printed.

To get around Skeinforge not spotting the bridge I set the infill starting angle to 90° so that the first bridge layer happens to be in the right direction anyway.

This workaround is OK when you have just one layer that bridges. With multiple layers you might need to slice with different angles and then splice the gcode together, but that is getting very inconvenient.

I normally print Mendel90 parts with 0.4mm layers, but I print the duct with 0.35mm layers in order to stretch the filament tighter, so that it bridges the large gap with less droop. The fact that it isn't detected as a bridge means that special bridging settings can't be applied.

When it comes to the new duct this strategy doesn't work because every layer of the sloping bridge advances left with nothing underneath. So consecutive layers are all bridges at the left edge. With normal 90° infill rotation every second layer has its infill changing direction in mid air. It is supported a little way back, so only small loops hang down, but that makes the inside of the duct very ugly and can't be good for airflow. Also if I print it with 0.35mm layers then the extra tension makes it tend to curl upwards and brush the nozzle, leaving brown marks on the top surface.

I could set the infill rotation to zero so that every layer is the right direction for the bridge but that would lead to a weak object, especially where the infill is sparse, so I haven't tried it. What is needed is a slicer that can split the sloping roof layers into a left unsupported edge that is printed as a bridge and the rest that is printed with normal diagonal infill. I know that other slicers can have different infill patterns within one island, so I decided to try them out with this object.

Cura 15.04.3

Cura seems to display infill as solid yellow in its layers view, so I used gcode.ws to display the gcode.Cura doesn't detect a bridge and just uses diagonal infill all the way. Interestingly it doesn't connect the ends of the infill, it does a short move at high speed with no retraction. Also it doesn't seem to have any retraction when it moves significant distances across the infill. This is one of the reasons I don't use Cura. I need retractions before all moves longer than say 1mm otherwise it leaves a trail behind and the next line doesn't start properly as there is missing plastic.

KISSlicer 1.1.0.14

KISSlicer shows some errors in the STL but the colour it uses to highlight them isn't in the key, so I don't know what it thinks is wrong. There are no errors in Netfabb Basic so I am pretty sure the file is OK.It too doesn't recognise the bridge and just does normal diagonal infill over it, using a colour scheme that is very difficult to see!

One odd thing is seems to do is inset the internal walls a little further on the last layer below this one, perhaps to give the infill more area to land on.

Slic3r 1.2.9

Slic3r actually detects it as a bridge but gets the angle slightly wrong.Two infill lines start or end in mid air. I discovered though that if I rotate it 90° the infill comes out correct.

This is a shame because I orientate it length ways for printing. That is because on a moving bed Y axis you want to minimise the Y movement to keep the object in warm air.

The next layer does exactly what I want. I.e. it does horizontal infill where there is nothing underneath but reverts to normal diagonal infill where there is something below.

So far so good but after a few more similar layers it starts to go a bit wrong.

It gets the boundaries of the bridge region wrong. It has a few lines of infill turning in mid air at the right hand side. Further up the slope it gets the left hand side wrong as well. I suspect it is because the slope slants left to right.

Further up it gets a bit more strange.

I haven't tried printing it but I suspect it would come out not too badly, with just a few small loops hanging down. At least it does logically the right thing, shame about the bugs in getting the bridge angle and region accurate.

CraftWare 1.13 beta

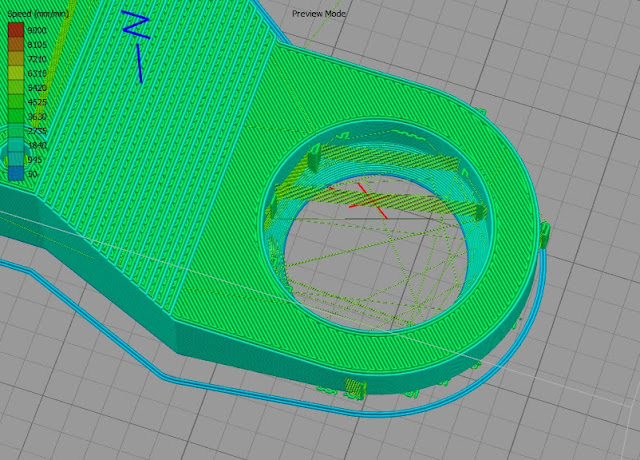

This is a late addition suggested in the comments. Perhaps the nicest user interface of all but it doesn't detect bridges at all in this object.Simplify3D 3.0.2

Since none of the free slicers I know of got this right I decided to try a paid for one. With a single outline it fails to detect the first bridge and just does diagonal infill in mid air.On subsequent layers it does seem to divide the layer correctly into a bridge region and a normal region but gets the infill direction in the bridge area completely wrong.

With two outlines it gets the main bridge correct but the slope now doesn't have a separate bridge region, just diagonal infill. That is except for just one layer and that also has the direction wrong.

The odd layer corresponds with the solid support diaphragms over the screw holes.

This does print slightly better than the Skeinforge one but only because the extra outline means the infill lines don't need to overhang quite as far.