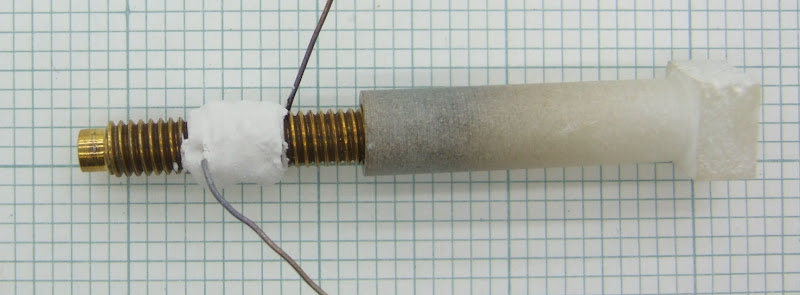

I replaced the 12mm diameter PTFE barrel with the recommended 16mm. Rather than make a new clamp I turned down the top end to 12mm.

I also replaced the woven insulation I was using with PTFE insulation. This is good for 250°C, which is fine for the thermistor but still a bit low for the heater. With this heater I brought out the nichrome tails which probably get hotter than the covered part of the winding. I think I prefer the way I have made my other heaters, which is to put the connections to the copper wires under the heater insulation. That way the copper wires never get any hotter than the body of the heater.

I put a pipe clip round the end of the PTFE to compress it against the screw thread. In an attempt to find out why my previous PTFE barrel deformed so much I made some temperature measurements with a different thermocouple to the one I used before, just in case it was faulty.

These are the temperatures I get with my software set to 200°C :-

The control of the nozzle temperature is very good, +/- 1°C. The other measurements show just how good an insulator PTFE is compared to the soapstone I mentioned in my previous article.

I think my problems stem from the fact that the heater barrel is quite a bit hotter than the nozzle. With the fan on, cooling the nozzle, the temperature difference will be even higher. It must have reached the point where PTFE starts to melt. I will try extruding without the fan from now on as I think that is what causes the PTFE and J-B Weld to give up. I might need inter layer pauses.

Compared to my first attempt at the extruder I have made the following improvements :-

- The steel cable for the flexible drive is now the recommended 3mm rather than 2.5mm.

- The drive screw has been replaced with one that has correctly centered bearing lands. This completely fixes the modulated filament I was getting before.

- The springs are much stronger which means I don't need to tighten them as far, making assembly quicker.

- The lock nuts on the studding have been replaced with plates which also make assembly and disassembly easier.

- The PTFE barrel is now the recommended 16mm rather than 12mm.

- The PTFE barrel is pinned into the clamp rather than relying on friction alone.

- The heater barrel is held into the PTFE with a pipe clip.

- The nozzle is now removable and has a shallower and tapered exit hole.

- The thermistor is closer to the heater so my on off control cycles much faster and keeps within +/- 1°C compared to +/-3°C with my one piece nozzle.

So far I am finding that without the fan I need to extrude slower to get the same results I was getting before.